Nhanganyaya

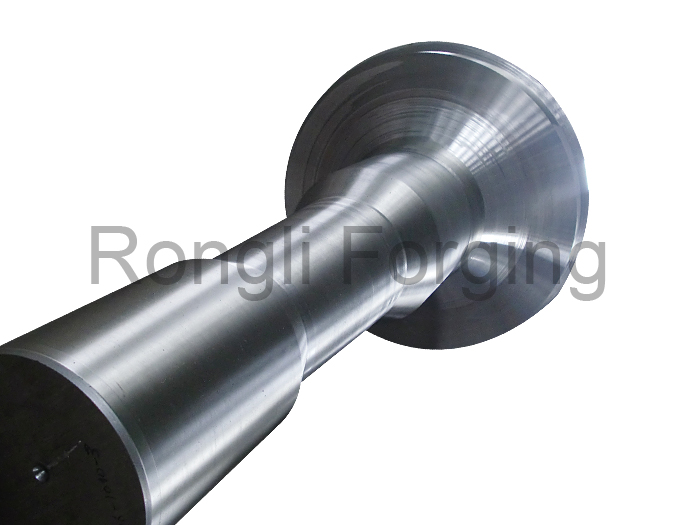

Rongli Forging Co., Limited inokwanisa kupa shaft yefoge & yemuchina inosvika 20 metres (66 tsoka) kureba uye 70 matani (44,000 lbs.) muhuremu.Yakasiyana-siyana yemagiredhi ezvinyorwa kune akasiyana zviyero zviri kuita pano muchitoro chedu chemazuva ano.Mashaft edu anotaurwa zvakanyanya anotumirwa kuNorth America, Europe, Australia, South Africa, mumaindasitiri eShipbuilding, kugadzirwa kwemagetsi emhepo, mine & simbi kugadzirisa, inorema indasitiri michina, simbi, nezvimwe.

Material

| Standard | |||||

| North America | Jerimani | Britain | ISO | EN | China |

| AISI/SAE | DIN | BS | GB | ||

| 304 | X5CrNi18-10 | 304S15 | X5CrNi18-10 | X5CrNi18-10 | 0Cr19Ni9 |

| 316 | X5CrNiMo17-12-2 | 316S16 | X5CrNiMo17-12-2 | X5CrNiMo17-12-2 | 0Cr17Ni12Mo2 |

| X5CrNiMo17-13-3 | 316S31 | X5CrNiMo17-13-3 | X5CrNiMo17-13-3 | X5CrNiMo17-13-3 | |

| 1020 | C22E | C22E | 20 | ||

| 1035 | C35E | C35E | C35E4 | 35 | |

| 1040 | C40E | C40E | C40E4 | 40 | |

| 1045 | C45E | C45E | C45E4 | 45 | |

| 4130 | 30CrMoA | ||||

| 4140 | 42CrMo4 | 708M40 | 42CrMo4 | 42CrMo4 | 42CrMo |

| 4330 | 30CrNiMo | ||||

| 4340 | 36CrNiMo4 | 816M40 | 40CrNiMo | ||

| 50B | E355C | S355JR | Q345 | ||

| 4317 | 17CrNiMo6 | 820A16 | 18CrNiMo7 | 18CrNiMo7-6 | 17Cr2Ni2Mo |

| 17CrNiMo7 | |||||

| 30CrNiMo8 | 823M30 | 30CrNiMo8 | 30CrNiMo8 | 30Cr2Ni2Mo | |

| 34CrNiMo6 | 817M40 | 34CrNiMo6 | 36CrNiMo6 | 34CrNiMo | |

| Chero rimwe giredhi rekushandisa sezvinodiwa nemutengi | |||||

Forging nzira: Vhura die forging / mahara forging

1. Material: Carbon simbi, alloy simbi, Stainless simbi

2. Material standard: DIN/ ASTM/AISI/ASME/BS/EN/JIS/ISO

3. Mechanical properties: Maererano nezvinodiwa nevatengi kana chiyero.

4. Huremu: Kusvika ku70 Matani ekupedzwa kwekugadzira.90 Matani eingot

5. Kureba: Kusvikira ku 20 metres yekugadzira

6. Delivery Status: Kupisa kurapwa uye rough machined

7. Maindasitiri: Kuvaka ngarava, kugadzirwa kwemagetsi, mine & simbi kugadzirisa, inorema indasitiri michina, metallurgy, nezvimwe.

8. Kuongorora: Kuongororwa kwemakemikari ne spectrometer, Tensile test, Charpy test, Hardness Test, Metallurgy test, Ultrasonic test, Magnetic Particle test, Liquid Penetration test, Hydro test, Radiographic test inogona kushandiswa.

9. Kuvimbiswa Kwehutano: Per ISO9001-2008